Bearing Rings

HQW high-precision ball bearings are typically made from corrosion-resistant, martensitic steel alloys. As well as 9Cr18 (equal to SUS440C) HQW bearings can use X65Cr13.

For spindle bearings and other demanding applications, such as medical devices and food processing, the highly corrosion-resistant nitrogen alloy steel X30CrMoN15-1 (HQW designation 30X) can be used. This highly-refined stainless steel has a very fine grain structure which enhances its mechanical properties.

Advantages of 30X

|

30X Applications

|

Corrosion Resistance

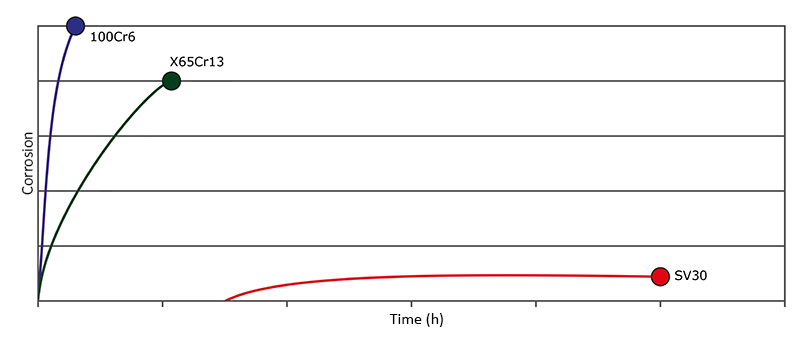

The graph below illustrates the degree of corrosion over time for the high-performance material SV30 (30X), compared with traditional bearing steels 100Cr6, 9Cr18 and X65Cr13.