Non-magnetic metal options are typically martensitic steels which do not reach minimum hardness levels for most bearing applicatons and are only suitable for low loads and speeds. To address this, HQW has introduced a range of bearings produced from fully non-magnetic steel which can reach minimum hardness levels of 60HRC.

Advantages of HQW Non-Magnetic Bearings:

Typical Applications:

|

Fully non-magnetic bearings incorporate plastic cages and ceramic balls

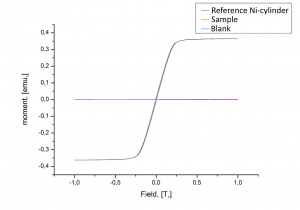

Graph Comparison |