Open and sealed spindle bearings can be easily distinguished by their design. It is also possible to specify whether the inner ring or outer ring is produced with one shoulder removed. |

|

Open DesignOpen spindle bearings make optimum use of the internal space by allowing a higher number of balls and a window cage. This results in maximum load carrying capacities and therefore maximum bearing life. This open design is recommended for oil lubrication, as it allows relubrication using spacers. No dirt must be permitted to enter the bearing and continuous relubrication should be used. |

|

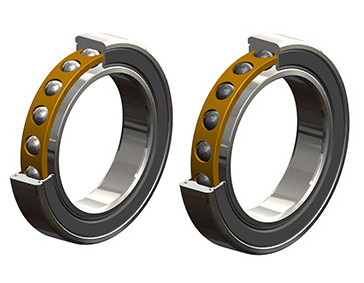

Sealed DesignSealed HQW spindle bearings generally have non-contact seals on both sides, which ensure improved protection against contaminants such as dust which could damage the internals of the bearing. This design also restricts the leakage of lubricant out of the bearing. The use of seals is recommended for applications where lifetime grease lubrication is a requirement. Since these are non-contact seals there is no negative effect on friction or speed ratings. HQW seals are made of fluororubber which can withstand peak temperatures of 230°C. The material possesses a very high resistance to grease and mineral oil. Further advantages of the sealed design include ease of handling and trouble-free installation, making it particularly suitable where bearings are being replaced. |

|

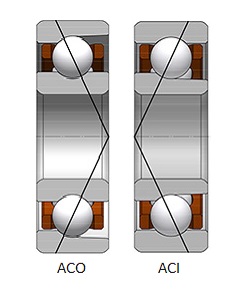

Special Design ACIAs a general rule, spindle bearings have the open shoulder on the outer ring (ACO). However, for some special applications the open shoulder can be positioned on the inner ring (ACI) (e.g. dismountable bearings). |

|